Why should you use the BMG?

Get stronger, more beautiful finished products at a lower mass production cost

The BMG (Bulk Metallic Glass) can be printed or injected into a mold, to produce a finished part, with a time reduced by 70% compared to other materials used in the metallurgical sector.

It also guarantees the final product a resistance 4 times higher than any other material and very high resilience (the ability of an object to spring back into shape).

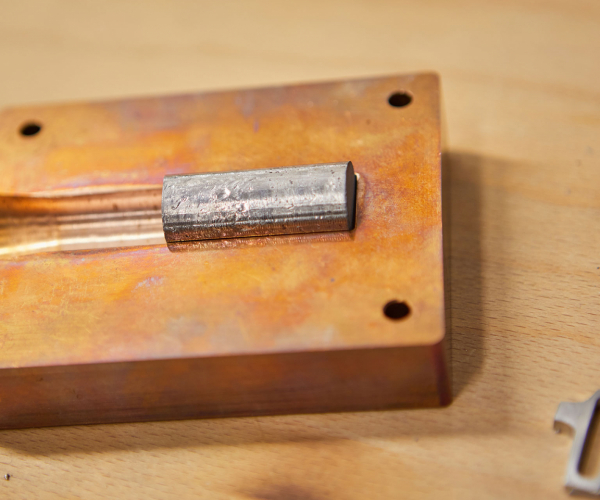

What we can produce with BMG

We have already made jewels for leading brands in the fashion industry, tools such as pliers, gears and machinery parts, electrical covers and parts of innovative devices, such as smartphones. We have also reached excellent results in producing screws, parts of sports accessories such as golf clubs or tennis rackets, medical and surgical devices, and much more.